Overview

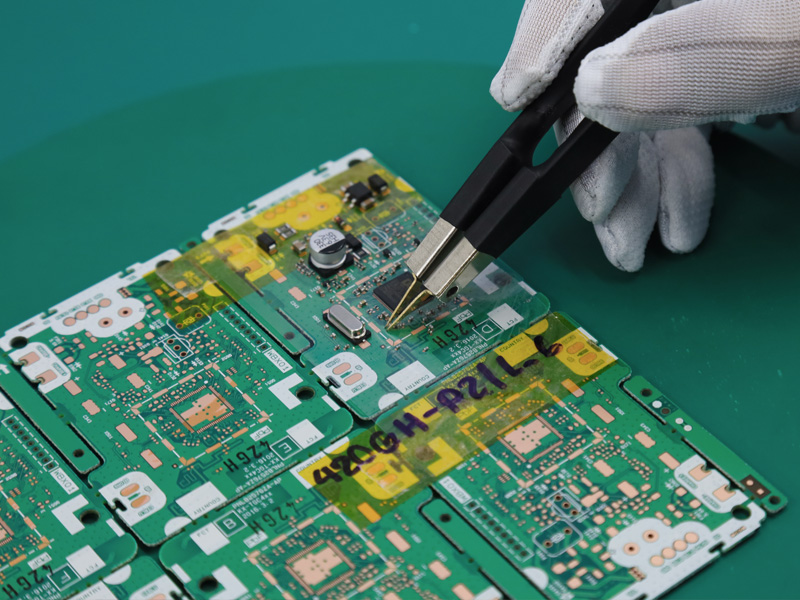

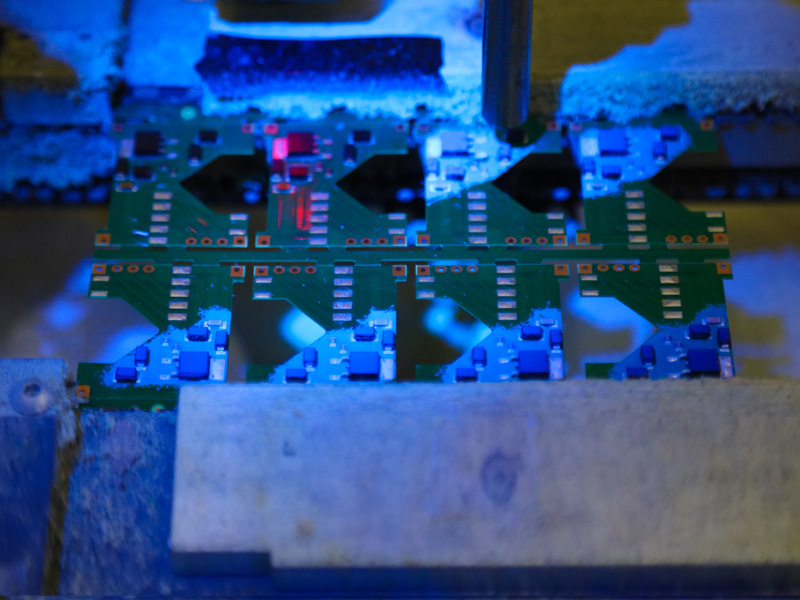

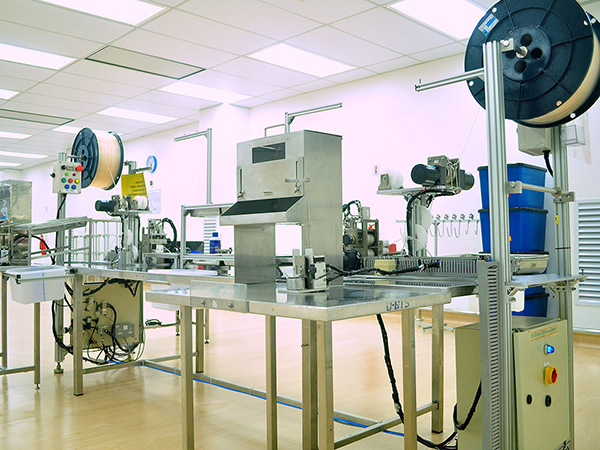

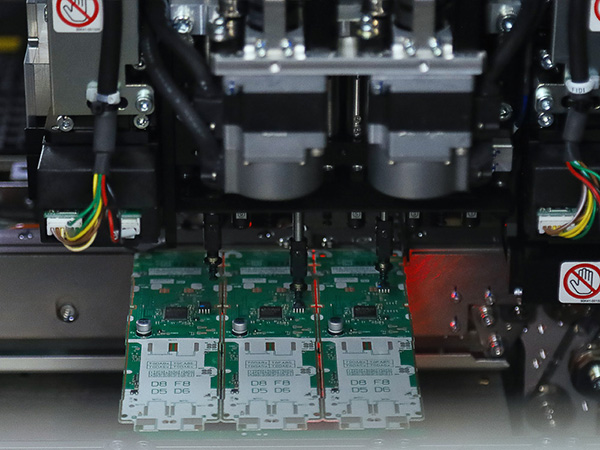

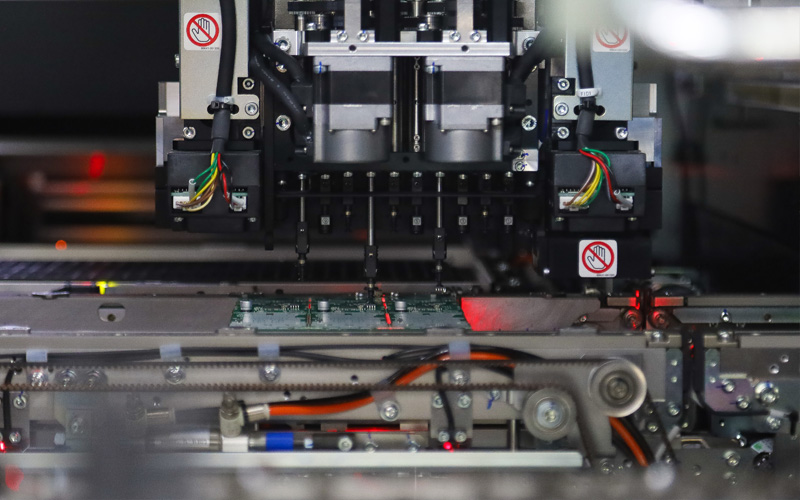

We are an EMS (Electronics Manufacturing Services) Solution Provider with services extended from Printed Circuit Board Assembly (PCBA) to complete Box Build Turnkey Solutions, Medical Assembly with Cleanroom facilities.

Eastool is built on the foundation of an over 30 years track record of serving global MNCs and OEMs requiring sophisticated technology and consistent high QA standards, which become the hallmark of Eastool as well as setting it apart from other EMS providers.

One-Stop Electronics Manufacturing Services Provider.

Our experience and expertise in Electronics Contract Manufacturing has lent us successful business partnerships with multi-national corporations who are prominent manufacturers of hi-tech electronic equipment as well as household electronic appliances.

Our Mission.

To emulate the mission of our parent company, GROP Co. Ltd. of “ Triple Win ” to grow together with customers, employees and GROP of companies, thus providing services & products of outstanding quality with a goal towards zero-defect and total customers satisfaction.

Our VISION.

To become the leading one-stop solution provider in Printer Circuit Board Assembly (PCBA) and OEM Solution Provider in Malaysia and expand globally to achieve worldwide international recognition.

Company Objectives.

To be flexible and sensitive to market change by developing and motivating individual, ready for cultural change that lead to perfect customer satisfaction with Quality, Cost and Delivery.

Corporate Motto

We use the term “Triple Win” to express the corporate stance of the entire GROP Group, transcending differences in business content and work types. The "Customers" who request work, the "Workers" who respond to them, and the "GROP" of companies who create the operation and place must be able to obtain benefits and effects from each other. This is because work can grow only when these three parties are satisfied together, and it is a condition for establishing a lasting relationship. We reflected these thoughts in the “Triple Win”.

- Actor (Worker)

- Actor (Worker)

- Customer

- Customer

- GROP Companies

- GROP Companies

Developmental Milestones

We are committed to achieving product quality, cost efficiency and realizing our delivery promise to our customers.

| Timeline | Achievement |

|---|---|

January 1993

|

Company incorporated in Malaysia |

January 1994

|

Printer Circuit Board Assembly for Fax Machine & CTV |

November 1994

|

Acquired Auto Insertion (AI) |

July 1996

|

Acquired Surface Mounting Technology (SMT) |

January 2007

|

Box build with Turnkey Solutions |

January 2009

|

Full Turnkey & Engineering Services |

September 2011

|

ODM / OEM for RF Tuner |

July 2015

|

2nd New Plant with Class 10K Cleanroom Facility for Medical Products |

January 2020

|

3rd New Plant at Indahpura, Kulai producing PMC Filter |

Quality Policy

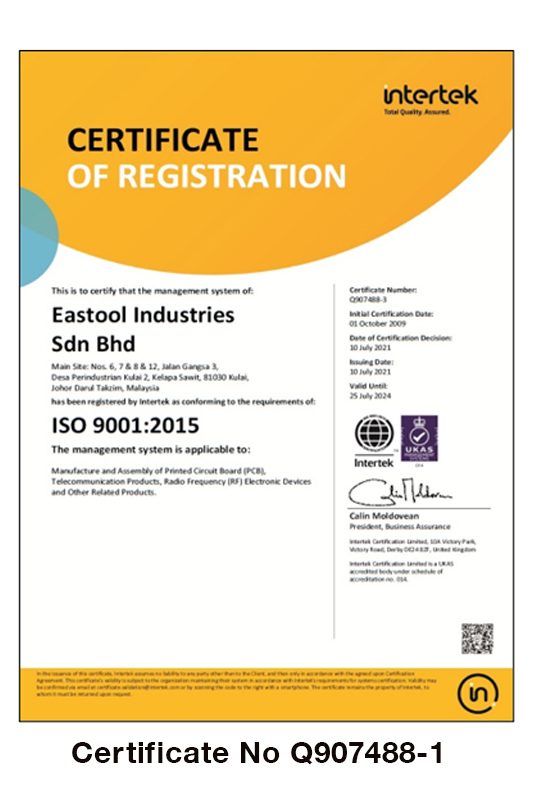

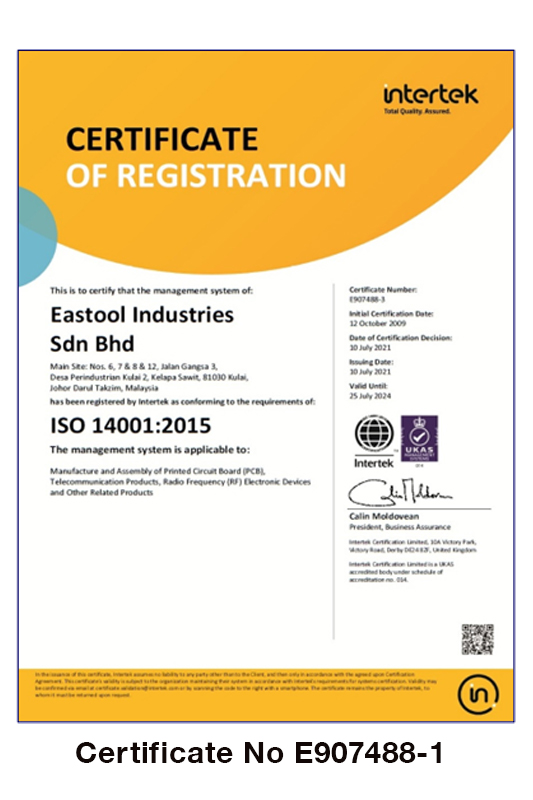

The ISO certifications are further strengthened by our core quality assurance policies, which represent our overall organizational values that translate into positive commitment for the benefit of our employees and customers.Quality

To adopt the ISO Quality Management System, which systematically enhance the consistency of Quality in our products.Cost

Reduce Line-Fail-Out, improve Productivity and Efficiency.Delivery

Realizing committed delivery schedule.System

Continue review and improve the quality management systems and organizational structure.Quality Assurance Certificates

In Accreditation, Licensing and Certification

To position our company above the rest in the industry, we are recognized for what we do and what we are able to do.

- Strategic Business Unit (SBU)

- Block Quality Assurance System

- IPC PCBA Standards

- High-Mix Low Volume (HMLV)

- High Mix High Volume (HMHV)